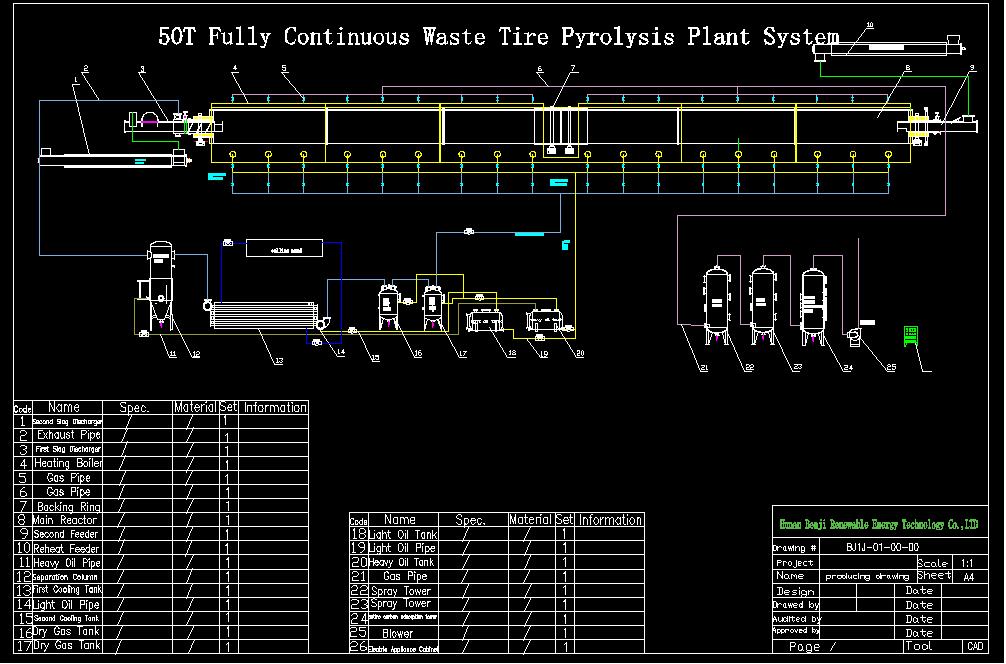

Fully Continuous Scrap Tyre Scrumb Waste Rubber Pyrolysis Project Plant 50tpd

https://www.youtube.com/channel/UCUcoG6jG0-BQr466IZ-FO8Q

Capacity:50TPD

Technology:

1.Our pyrolysis plant has auto feeding system. The material goes from underground to the feeder and then goes into reactor,which is automatic operation.And no flying dust in workshop at all.

2.We have energy saving technology:the fuel is heated at the bottom of the reactor indirectly (flame towards to the ground),with 8 burners evenly installed on the reactor,which can transfers heat energy equally to the reactor all around in 360 degree. In this way,it will save a lot of fuel energy and also protect the reactor for longer service life.

3.At present, the biggest problem for continuous production of rotary reactor is thicken coking which will be formed continuously when feeding materials are affected by high temperature in the reactor, which not only makes the reaction unable to proceed, but also damages the equipment quickly.We have special advanced technology which can constantly remove the coke in the reactor to ensure the continuous feeding and pyrolysis that will greatly extend the life of the equipment and also increase production efficiency.

4.During heating process, the reactor will rotate automatically and slowly,regularly 3mins per round, the material will pyrolysis completely after from one end to the other end.And the carbon black quality are much better with oil content less than 0.3% only.The carbon black quality is fine powder.

5.The syn gas generated from the system will be used to support continuous heating. The fully continuous system even dose not need any extra fuel once the system is started up. Because the syn gas will be far enough for the heating purpose. It will save much of the fuel cost.

6,High oil yield technology.Generally,there is still big quantity of rest syn gas after burning,we have technology to convert syn gas into fuel oil again,thus it will increase the oil yield rate to 42-48% (regular rate around 40% only).

7.With our special soft sealing technology,the whole pyrolysis plant is totally air tight without leakage problem. So there is no harmful gas or bad smell coming out from the system. And the system has automatic depressur-ization valve,so the pressure inside of the reactor wont never be dangerous.

8. All the carbon black and steel wire collecting system covered in air tight system and connected to the dust collecting equipment. So the whole workshop will be tidy and with lower noise.

9. We use water pools for cooling only (not N2).The water are used circularly from equipment into pool,which will save a lot of cost per day.

10.Muti-graded discharging system with water jacked promise low temperature while discharging.

11. All of our system has passed the ISO,SGS and CE certificates.